Web Menu

Product Search

Exit Menu

- SCB11, SCB12, SCB13, SCB14, CB18 Series Epoxy-Resin Insulation Dry-type Transformer

- SG(B)11~18 Series Un-Packed H Grede Dry Transformer

- SCB11 Load Voltage Dry-type Power Transformer

- SCBH15 Amorphous Alloy Dry Type Transformer

- SZ13 Series 35kV Low-loss And On-load Regulation Transformer

- S13~S22 Series 10kV-35kV Low-loss And Non-exciting Regulation Oil-immersed Power Transformer

- S13(22)-M. ZT Distribution Transformer On-Load Automatic Tuning Capacitor

- SH15-M Sealed Non-Crystalline Alloy Power Transformer

- Supporting Dedicated Connection Transformer

- ZGS13一H(Z) Combined Transformer

- YB-PRE-Compact substations (European Box Variable)

- ZGS20-Z·G Combined Transformer For Photovoltaic Power Generation

NEXT:SG(B)11~18 Series Un-Packed H Grede Dry Transformer

- Description

-

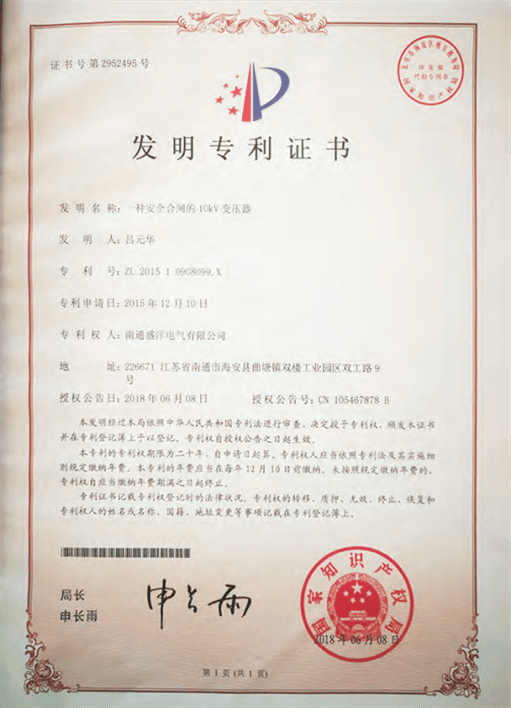

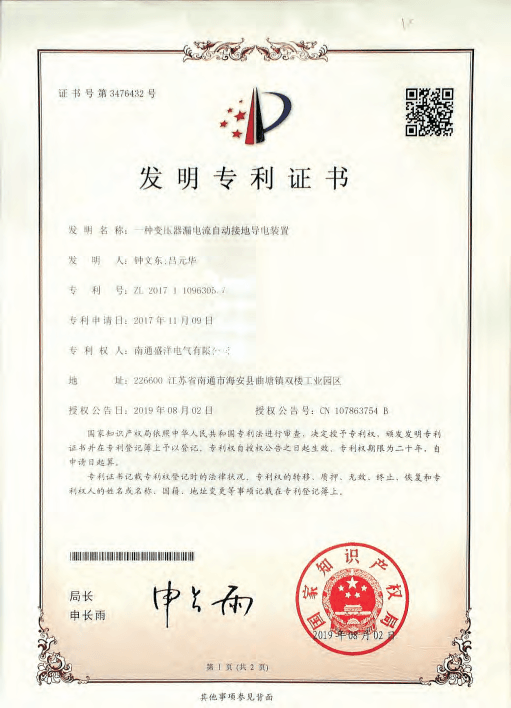

10kV Grade Products:The 10kV grade products are considered moderate voltage, making them easier to handle. Consequently, many companies adopt a traditional double-winding, two-division structure for the insulation design. In this configuration, the low-voltage winding is axially wrapped around the two high-tension coils. During the pouring process, when filling the coils, two sets of coils are electrically connected to maintain uniform lead-out.35kV Grade Products:The 35kV grade products operate at a higher voltage level. To ensure electrical performance, especially in terms of local power distribution and resistance to lightning impacts, companies have developed a unique structural design for the low-voltage coil. This structural processing, for which the company currently holds an application patent, allows for a special configuration of the low-voltage coil. By optimizing the design of the low-voltage coil, the number of turns in the high-tension winding is reduced, thus minimizing the number of coil layers. This results in a more uniform distribution of current within the coil.

Related Products

-

SCB11, SCB12, SCB13, SCB14, CB18 Series Epoxy-Resin Insulation Dry-type Transformer

Cat:Products

Security and Fire Resistance: The product is designed with a focus on security and fire resistance.

See Details -

S13(22)-M. ZT Distribution Transformer On-Load Automatic Tuning Capacitor

Cat:Products

The S13(22)-M. ZT distribution transformer with an on-load automatic tuning capacitor is equipped wi

See Details -

SH15-M Sealed Non-Crystalline Alloy Power Transformer

Cat:Products

The transformer is a fully oil-filled sealed type, and its design principle is similar to that of a

See Details -

Supporting Dedicated Connection Transformer

Cat:Products

The Supporting Dedicated Connection Transformer is an essential component in electrical systems that

See Details -

YB-PRE-Compact substations (European Box Variable)

Cat:Products

The YB type compact substations, also known as European-style box transformers, conform to the GB174

See Details -

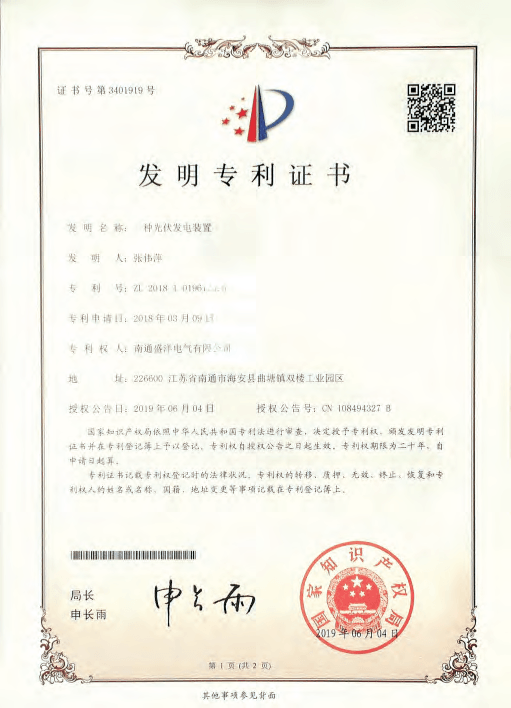

ZGS20-Z·G Combined Transformer For Photovoltaic Power Generation

Cat:Products

Photovoltaic power is a rapidly growing clean and renewable energy source, both domestically and int

See Details -

YBM (P) 35kV-Class High/Low Voltage Prefabricated Transformer Substation For Wind Power Generation

Cat:Products

The Integral Type Transformer for Wind Power Generation is a specialized power equipment that integr

See Details -

Containerized Energy Storage System (Customizable)

Cat:Products

This system features high system integration, combining data monitoring, video monitoring, power dis

See Details -

THREE PHASE GROUNDING TRANSFORMER

Cat:Products

This type of transformer uses Z-type wiring (or zigzag wiring). The key difference between this tran

See Details -

QSG/SG Three-Phase Dry Isolation Transformer Series

Cat:Products

The QSG/SG three-phase dry isolation transformer series stands out as a versatile range of electrica

See Details

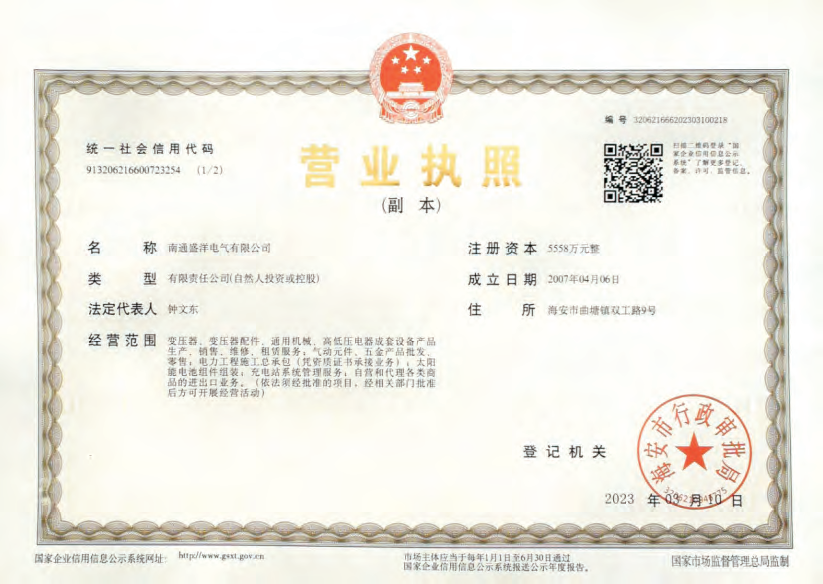

We are a professional China ODM SCB11 Load Voltage Dry-type Power Transformer manufacturers and SCB11 Load Voltage Dry-type Power Transformer suppliers, Our factory specializes in the manufacture of power transformers, rectifier transformers, Box-type transformer substations, wind power transformers, and its complete sets of products. We occupiers an area of 26500m2, of which the construction area is 13800m2; the fixed investment is RMB 35,800,000; We have many main product equipment and full sets of inspection equipment, such as vacuum drying system, automatic vacuum casting system, corrugated oil tank product line, slitting line, horizontal cutting line and automatic foil winding machine and son on. Our technology is strong, the manufacture process is advanced, and equipment and testing modes are complete.

-

The installation of an oil immersed transformer is a critical process in electrical power systems, r...

READ MORE -

Oil immersed transformers are essential devices in electrical power systems, designed to step up or ...

READ MORE -

In the realm of electrical power distribution and transmission, selecting the right transformer tech...

READ MORE -

Oil-immersed transformers are the workhorses of electrical power distribution, renowned for their ef...

READ MORE -

In the vast and intricate network of the electrical grid, from power generation plants to local dist...

READ MORE -

In the vast and complex network of electrical power systems, one component remains a cornerstone of ...

READ MORE

Load voltage regulation refers to the ability of a transformer to maintain a consistent output voltage under varying load conditions. The comparison between the load voltage regulation of Dry-type Power Transformers and oil-filled transformers involves several factors:

Temperature Stability:

Dry-type transformers generally exhibit better temperature stability than oil-filled transformers. This is because the epoxy resin used in Dry-type transformers has a lower coefficient of thermal expansion compared to oil, leading to more consistent performance over a range of temperatures.

Cooling Mechanism:

The cooling mechanisms in Dry-type transformers typically involve natural convection or forced air, allowing for efficient heat dissipation. In contrast, oil-filled transformers rely on oil for cooling, and the efficiency of cooling can be influenced by factors like ambient temperature.

Dielectric Properties:

The dielectric properties of the insulating materials in Dry-type transformers contribute to better voltage regulation. Dry-type transformers often use materials with high dielectric strength, enhancing their ability to maintain voltage stability.

Maintenance Requirements:

Dry-type transformers generally have lower maintenance requirements compared to oil-filled transformers. The absence of oil eliminates the need for regular oil testing and reduces the risk of issues like oil contamination affecting the transformer's voltage regulation.

Environmental Considerations:

Dry-type transformers are considered more environmentally friendly than oil-filled transformers due to the absence of oil, which eliminates the risk of oil leaks or spills that could impact the transformer's performance.

Size and Weight:

Dry-type transformers are often more compact and lighter than oil-filled transformers, which can positively impact their voltage regulation. The shorter winding lengths and reduced magnetic path in Dry-type transformers contribute to lower impedance and improved voltage stability.

Response to Overloads:

Dry-type transformers may have a better response to overloads, as their compact design allows for faster dissipation of heat generated during overload conditions. This can help in maintaining more stable voltage levels compared to oil-filled transformers.

Safety Considerations:

Dry-type transformers are generally considered safer in terms of fire risk and environmental impact. The fire-resistant properties of the materials used contribute to a lower risk of thermal runaway, ensuring better safety and reliability in terms of voltage regulation.

While Dry-type transformers offer advantages in terms of voltage regulation, it's essential to note that the choice between Dry-type and oil-filled transformers depends on specific application requirements, environmental considerations, and factors such as cost and available space. Both transformer types can be designed to meet various voltage regulation standards based on industry requirements.

For exclusive deals and latest offers, sign up by entering your email address below.

+86 137 6109 6177 / 0086-18906278996

9 Shuanggong Road, Shuanglou Industrial Park, Haian, Jiangsu Province, P.R.

Mobile Terminal

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体